What Is Alignment Coupling?

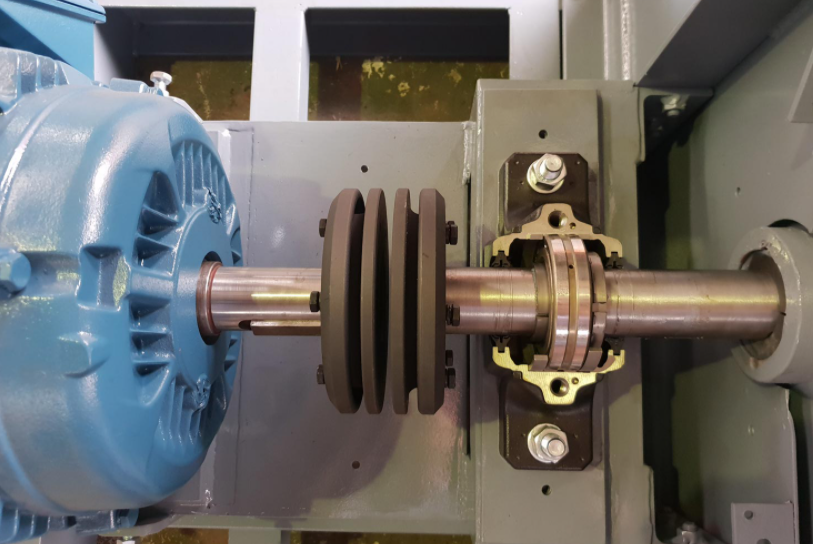

Alignment coupling is also known as shaft alignment, which is a prerequisite or an absolute requirement for machinery before it put in service. In this process, two or more shafts are aligned with each other to within a bearable margin.

It also describes as an essential that make sure the pump has a trouble-free mechanical operation, and it is to prevent damage to the transmission elements. In this process, it is necessary to maintain the prescribed distance between the coupling halves.

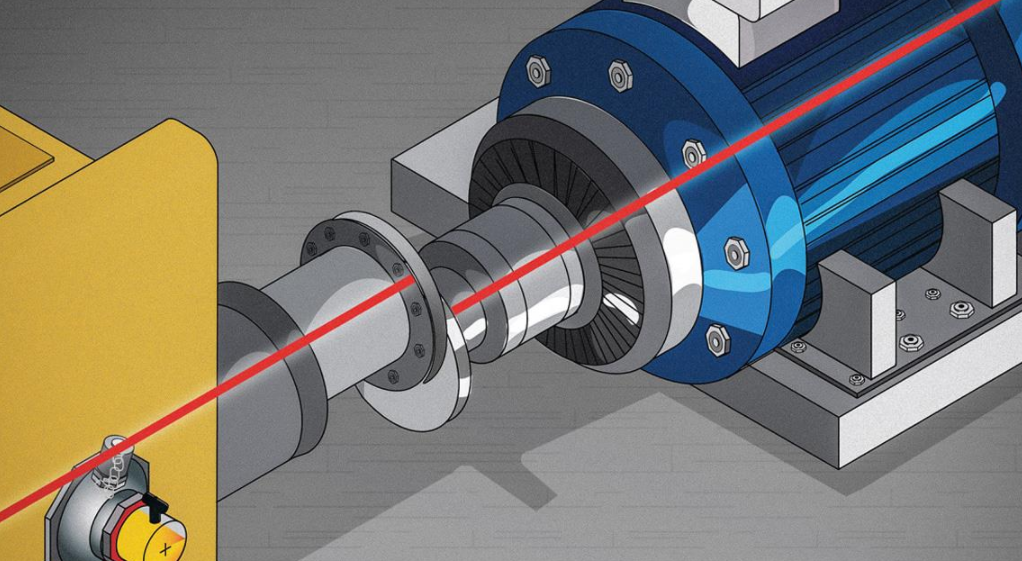

This process is mandatory to prevent any kind of malfunction, accidents, and injuries. Maintaining the distance and positioning the shafts are done by some particular tools. Laser shaft alignment is its examples that ensure perfect coupling and bear well below the recommended margin. Laser technology is used in the laser shaft alignment. Although it is not a new concept, one that has undergone this process becomes reliable and accurate. Gyroscope-based systems are also used for this coupling. But these are cheaper, and they are not that much reliable and offer precision like laser systems, and these gyroscope-based systems are challenging to set up.

If the misalignment occurs between elements, then they fall into two categories; either it falls in angular misalignment or parallel misalignment. When the angular misalignment is experienced, the lines of shafts are at an angle, either vertical or horizontal, and on the same plane or maybe on a different plane. In comparison, parallel alignment occurs when the lines of shafts are parallel but are separated either vertically or horizontally. In both cases, laser shaft is used to correct the error.

Let’s take an example to understand it in more in-depth. The laser levelling tools are used to shoot a perfectly straight line that is minor. Likewise, shaft alignment, when works with laser technology, it also achieves the same goal. And in this process, three elements are used, including laser, sensor, and an electronic device. Additionally, this technology of alignment is applied to a wide variety of tools such as it used for gearbox and motor alignment, generators, turbines, propeller shafts, and compressors. And this process of alignment is used by a variety of industries such as construction industry, gas, oil, paper and pulp, wastewater management sectors, and pharmaceuticals, etc.

Alignment coupling when works with laser alignment; it makes the task of adjusting components so quick at a lower cost as well. And due to its fast working mechanism, it reduces the labour cost, saves much of the time, and makes setup fast.